Activities

Improvement and Promotion of a Technology Package for the Production of Powder from Turmeric for Commercial Application

(July 1, 2018 – June 30, 2021)

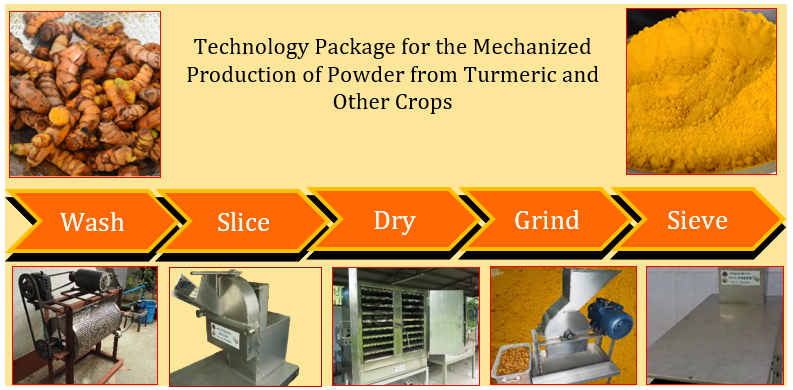

The ubiquity of products manufactured from turmeric rhizomes in commercial areas and retail markets across the country underscores the general acceptability and economic value of the rhizomatous plant. Since the crops are scattered in various parts of Zamboanga del Sur particularly in the municipality of Dumingag, the local government in cooperation with the Center for Agri-Fisheries and Biosystems Mechanization (BIOMECH) and the Department of Agriculture Bureau of Agricultural Research (DA-BAR) has developed a technology package that processes turmeric rhizomes and other root crops. The local processing center houses the technology package which includes a multi-crop slicer and chipper, multi-crop cabinet-type dryer, hammer-mill type pulverizer, and sieve separator. The enterprise has performed satisfactorily in the past years and has already created a dependable market for local farmers within the municipality.

The three-year project centers on the optimization of turmeric powder production in order to maximize machine performance and energy utilization, enhance product quality, and reduce overall labor requirement. It is composed of two components: optimization processes for technology commercialization of the turmeric powder production system, and development, testing, and evaluation of the commercial prototypes of the technology package for powder processing. The team responsible for the attainment of project objectives consists of Engr. Jose D. De Ramos, Project Leader and University Extension Specialist III; Engr. Marife R. Santiago, Study Leader and University Extension Specialist II; Engr. Roselle P. Barretto/Engr. Nina Mae G. Talaro, University Research Associate II; Jessica R. Cullat, Project Assistant I; and Edgardo M. De Mesa, Laboratory Aide II.

Some activities that were already undertaken include the characterization of some physical and engineering properties of fresh, dried, and powdered turmeric, characterization of microbial and nutritional properties of fresh and powdered turmeric, deployment of processing machinery that include solar tunnel dryer and multi-crop cabinet-type dryer at the project collaborator site, characterization of the blanching and drying characteristics of the turmeric rhizomes, and improvement of the existing drying system at the processing center for more efficient drying process and energy utilization.

Currently on its second phase, the project is now focusing on the improvement of process parameters that will maximize capacity and recovery, and minimize losses. This includes testing of the deployed machinery, design refinements, sensory evaluation of powdered turmeric and consumer acceptability analysis, and conduct of capability training on machine operation, maintenance, and good manufacturing processes. An improved technology package and processing center that will be able to produce turmeric powder and other organic products required by the existing market in the Zamboanga region shall be expected at the end of the project.

The processing steps involved in the production of powder from turmeric and the corresponding machines developed for the mechanization of the process (from left to right): washer, multi-crop slicer, cabinet-type dryer, pulverizer, and sieve separator.