FEATURES:

- Constructed from locally available materials

- Non-crushing type (shelled cobs are kept whole)

- Versatile (can shell corn for seed purposes )

- Suitable for all sizes of corn ears

METHOD OF OPERATION:

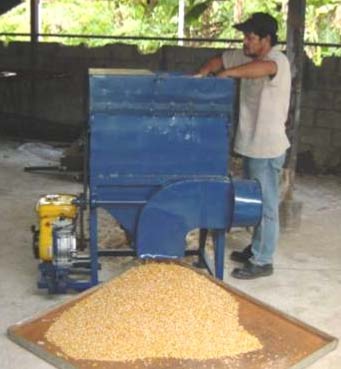

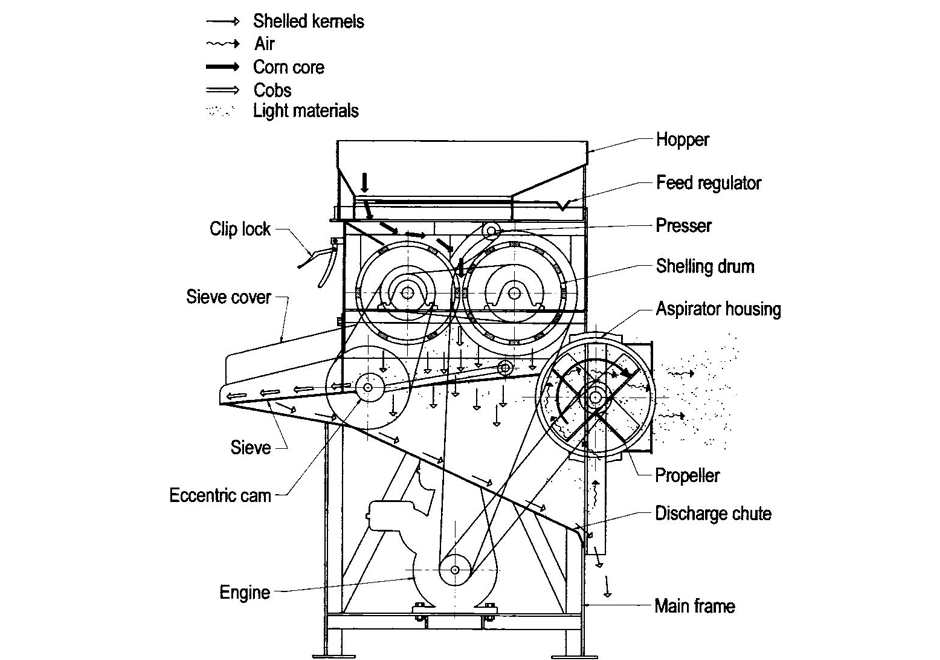

Prepare the sheller and the corn ears to be shelled. Orient the sheller in a way that the exit direction of the aspirator goes along with the wind direction if shelling is to be done outdoors. Place the collecting receptacles below the kernel discharge outlet. Start the engine and engage into the sheller with the use of the clutch. Load the corn ears into the hopper and open the flap to allow the corn ears to enter the shelling assembly. Corn ears are reloaded into the hopper when half of the capacity has been shelled. Continue shelling until all the corn ears are shelled. After shelling disengage the engine from the sheller and stop the engine. Collect and bag all shelled kernels and dispose off the cobs.

SPECIFICATIONS:

| Type: | |

| Shelling Unit:: | Helical two-drum with cylindrical presser |

| Separator: | Oscillating sieve |

| Cleaner: | Aspirating blower |

| Shelling capacity: | 0.8 to 1.0 ton/hr ( at 18-24% kernel MC wet basis) |

| Shelling efficiency: | 99% or higher |

| Dimensions (mm): | |

| Length: | 1200 |

| Width: | 1150 |

| Height: | 1255 |

| Weight: | 152 kg (without engine) |

| Power Source: | 6-7 Hp gasoline or diesel engine |

| Labor requirement: | Two to four persons |

For more information, contact:

The Program Manager

Center for Agri-Fisheries and Biosystems Mechanization

Institute of Agricultural Engineering

College of Engineering and Agro-industrial Technology

University of the Philippines Los Baños

College, 4031 Laguna, Philippines

Tel. No. (049)536-2686, Telefax No: (049)536-3606

Email: [email protected] or [email protected]

Website: http://iae.uplb.edu.ph/index.php/amdp

If you wish to have a copy of this machines just click here.